Automatic pipetting – both efficient and ergonomic

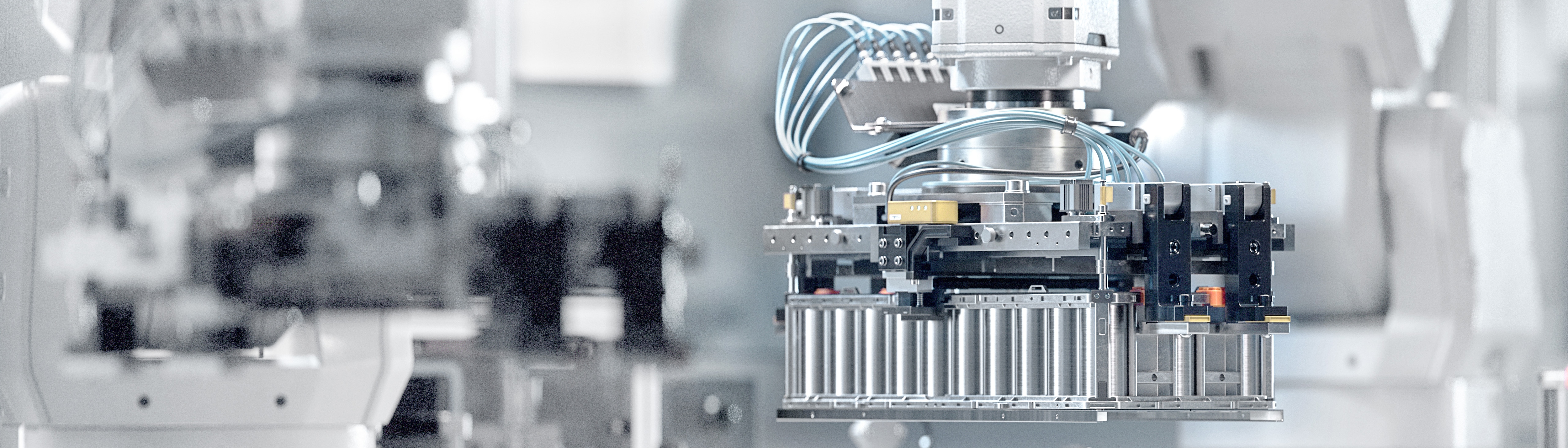

The exact and efficient transfer of samples in extremely small dosing volumes is essential in the life sciences industry. For this purpose, INTEGRA Biosciences AG developed a compact pipetting robot called ASSIST PLUS that draws and pipettes samples into the target container.

Part of this process is the automatic loading and ejecting of pipette tips, monitored by a customer-specific solution developed by Leuze specially for INTEGRA Biosciences based on the polarized PRK 3B retro-reflective photoelectric sensor.

Electronic pipetting – today a must in every lab

Modern laboratories, whether in the biotech or pharmaceutical industry or in the academic realm, process and analyze an increasing quantity of samples. Yet the sample volumes and the corresponding labware are becoming smaller. The high sample quantity and strict requirements on accuracy and precision make manual pipetting a great challenge for the users.

Furthermore, long, manual pipetting protocols can impact the health of the users, as classical, manual pipetting involves collecting and dispensing liquid using thumb movements. This can lead to the development of repetitive strain injuries. With modern pipettes, special focus is therefore placed on ergonomics by reducing the weight of the devices and by performing the pipetting operation electronically.

An advantage of ASSIST PLUS is that the users themselves no longer need to pipette. The pipette can be clicked into the ASSIST PLUS holder, and the protocol is performed automatically. To prevent cross contamination of samples during critical applications, pipette tips are used only once. ASSIST PLUS does this by automatically loading new tips and then ejecting them into the provided tip waste container after the pipetting operation.

Customer-specific solution for INTEGRA Biosciences

The life sciences industry and its wide-ranging disciplines are characterized by constant further development of the analysis methods. Among other things, flexible solutions are desired for the tasks performed in the laboratory. INTEGRA Biosciences therefore develops lab devices that are extremely versatile.

"In recent years, we have concentrated on the development of new, technologically advanced manual pipettes which, on the one hand, are easy to handle and, on the other, meet the ergonomic requirements of our customers," explains Stephanie Stursberg, product manager in INTEGRA Biosciences. It is especially advantageous that INTEGRA customers can operate the pipettes manually as well as use them as pipetting robots. "Thus, the lab equipment can be adapted to the current automation needs at any time," continues the molecular biologist. Today, the portfolio includes manual and electronic pipettes, semi-automatic pipetting devices with up to 384 channels as well as automated solutions, such as ASSIST PLUS.

Directly involved in the development of the ASSIST PLUS compact pipetting robot demonstrated here were project manager Andreas Städler as well as electronics developer Garry Müller. One of the many challenges was the automatic change of pipette tips and the monitoring of this process. It needed to be ensured that all pipette tips are loaded and, on completion of the process, ejected.

"To maintain the compact dimensions of the robot, we envisioned an integrated optoelectronic solution, consisting of sensor and reflector, for monitoring the tip handling," reports Andreas Städler. "Finding such a solution was no easy task. This module needs to be able to reliably detect pipette tips, which are transparent and – in some cases – less than a millimeter in diameter." Economical prerequisites and delivery times also play an important role. To meet all of these requirements, a customer-specific solution was developed jointly with Leuze specifically for INTEGRA Biosciences.

A customer-specific solution doesn't have to be expensive

There are many providers of retro-reflective photoelectric sensors. But only one was able to satisfy all demands – and could do so for the price of a standard solution: David Semprevivo from Leuze made it possible. Together with the Industry Manager for Labor Automation, Dr. Lutz Werner, who is based at the Leuze headquarters in Owen/Teck, the Swiss key account manager sought out possibilities that could turn this application request into reality.

The sensor-reflector solution that was found is based on the PRK 3B polarized retro-reflective photoelectric sensor from Leuze. This is the world's smallest retro-reflective photoelectric sensor with laser and autocollimation principle. With its small housing dimensions of just 32 x 11 x 17 mm in the standard compact version, it could easily be integrated in the likewise compact pipetting robot from INTEGRA Biosciences.

With special dimensions, deflected cable and special reflector, this solution became a complete product developed just for INTEGRA Biosciences. Especially for this, the subsidiary of Leuze electronic in Fluringen, Switzerland, set up a small warehouse so as to be able to flexibly respond to the quantities ordered by INTEGRA Biosciences at any time.

"It is important to us to be able to individually meet our customers' requests at all times and to make use of our years of industry experience in the area of laboratory automation," says David Semprevivo. "A fast delivery time is also a must for us." INTEGRA Biosciences can thereby be supplied with the requested quantities within no more than two days.

About the companies

INTEGRA Biosciences AG, Zizers (CH)

Founded in 1965, the company is headquartered in Zizers, Switzerland. There, nearly 100 employees develop devices for liquid handling and culture media production; 210 employees work for INTEGRA Biosciences worlwide. For the global sales of its lab devices and customer support, INTEGRA Biosciences has its own direct sales and support subsidiaries in the USA, Canada, China, Great Britain, France, Germany, Austria and Switzerland as well as a global network of sales partners.

Leuze

With curiosity and determination, the Sensor People of Leuze have been driving innovation and technological milestones in industrial automation for more than 50 years. They are driven by the success of their customers. Yesterday. Today. Tomorrow. The technology leader’s high-tech product range includes a number of different sensors for the field of automation technology. Among these are switching and measuring sensors, identification systems, and data transmission and image processing solutions. As a Safety Expert, Leuze is also focused on components, services and solutions for safety at work. Leuze concentrates on its core industries, in which the Sensor People have extensive, specific application know-how and many years of experience. These include intralogistics and the packaging industry, machine tools, the automotive industry as well as laboratory automation. Leuze was founded in 1963, headquartered in Owen/Teck in Southern Germany. Today there are more than 1200 Sensor People around the world who are working with determination and passion for progress and transformation to make their customers successful in a constantly changing industry. Regardless of whether in the technological competence centers or in one of the 21 sales companies, supported by more than 40 international distributors.