Stationary 1D / 2D code readers

Stationary 1D/2D code readers

Camera-based bar code readers for stationary use: These code readers reliably capture 1D- and 2D-codes; depending on the type, printed or directly marked, omnidirectional, static or in fast motion as well as inverse or mirrored codes. Various version are available with respect to size, degrees of protection IP 67 or 69K, speed or interfaces.

DCR 200i

Advantages for you

- Easy and fast commissioning: A wizard integrated in the WebConfig tool guides you quickly and easily through the setup process and simplifies commissioning. For simple applications, the DCR 200i can also be set up for the reading task without a PC using just two buttons on the device

- Codes can be read on various materials: Interfering reflections can be reduced thanks to exchangeable polarization filters and diffusor foils

- Detection, even at high object speeds: High reading performance and powerful LED illumination enable a good reading result even at high object speeds or partially damaged codes.

- Attractively priced thanks to modular set-up: Thanks to the modular design, the DCR 200i is exactly adapted to the requirements of your application with respect to function range and power.

Highlights

Seamless traceability of your products from production to the customer is getting increasingly more important. Whether for allergen management with food products, placement inspections in the pharmaceutical industry, shipping label monitoring in the packaging sector or testing of the product quality in the electronics industry – the fast and reliable identification of 1D- and 2D-codes is essential.

The DCR 200i dual code reader combines simple handling with high reading performance – even with demanding reading tasks – and thereby provides support with:

- Identification - ensuring that the label was printed with product/bar code and/or Data Matrix code

- Track and trace - traceability of ingredients and packed products during production.

Applications

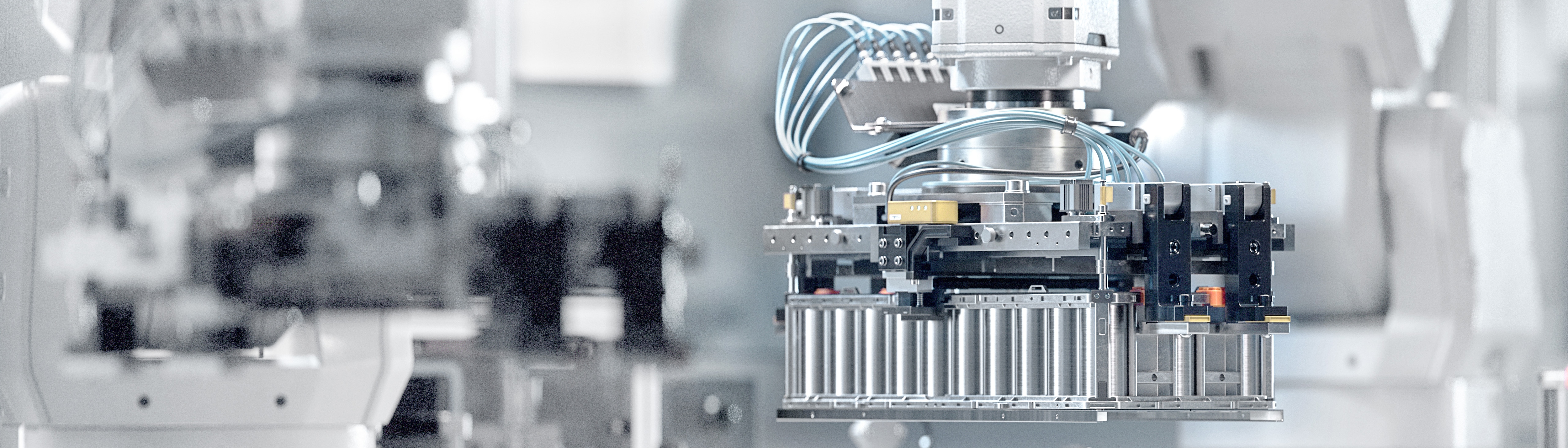

Code reading in the production area

Requirement:

In final assembly, codes are used for the traceability of individual components. These must be read on a conveyor line that – at times – moves at high speeds.

Solution:

Thanks to their high scanning rate, the DCR 200i 1D-/2D-code readers enable the reading of codes on quickly moving objects. In addition, optics models are available for various reading ranges.

Code checking in electronics production

Shipping-label inspection in conveyor and storage systems

Code inspection on pharmaceutical packages

Label inspection in the food industry

DCR 1048i

The high-performance code reading algorithm of the DCR 1048i ensures extremely high reading rates. As an option, this model has an improved algorithm specially conceived for DPM codes.

Advantages for you

- 1D-/2D-code reading with one image processing sensor

- Enhanced reading algorithm specially for DPM codes

- Fast commissioning

- Support of common industrial protocols

- Exchangeable lenses for flexibility in terms of distance, field of view and resolution

- Multicode decoding also possible

Applications

DCR 1048i: Simultaneous reading of multiple 1D and 2D-codes

Requirement:

A secondary packaging has both a 1D-code and a 2D-code. For quality assurance purposes, the codes are to be scanned before insertion as a pack of 5 into a carton. During the process, the codes are to be identified simultaneously with a single scan irrespective of the code type.

Solution:

The new DCR 1048i can read either single 1D and 2D-codes or any number of 1D and 2D-codes simultaneously without problem by means of multicode decoding.

DCR 1048i: Reading of codes printed directly on packaging material

Requirement:

A 2D-code is printed directly on secondary packaging. The decoding of these so-called DPM codes is essential for the traceability of the products.

Solution:

The DCR 1048i DPM Simple Vision sensor has an optimized reading algorithm which is specially designed for decoding codes that are printed directly on packaging.

DCR 1048i: Code reading for detecting the alignment of bags on conveyor lines

Requirement:

On bagged products, a code is printed on the rear side of the packaging. This code is to be used to check that all bagged products are aligned correctly before they are automatically packed into a carton.

Solution:

The DCR 1048i can identify the codes to check whether or not the bagged product is aligned correctly. Alternatively, pattern detection can also be used to detect the correct alignment of the bagged products.

DCR 50/55

Compact 1D- and 2D-code readers as module or in aluminum housing. CMOS imager and integrated decoder for all commonly used 1D and 2D codes. RS 232 or USB interface, one trigger input, one switching output, degree of protection IP 54.

Advantages for you

- Very small construction

- Ready to read all common codes

- RS 232 or USB interfaces

- Simple configuration with the Sensor Studio PC software

Applications

Manual code reading and reading in presentation mode

Requirement:

1D-/2D-codes must be read on samples by an automatic analyzer. Devices with modular construction are necessary for use in small automatic analyzers.

Solution:

With their very small size and open design, the DCR 50 1D-/2D-code readers can be optimally integrated in constrained spaces.

Code reading on reagents

Requirement:

1D-/2D-codes must be read on samples or reagents by an automatic analyzer. Devices with modular construction are necessary for use in small automatic analyzers.

Solution:

The DCR 55 1D-/2D-code readers can read codes in a large reading field on slowly moving objects. For very restricted installation situations, the DCR 50 is available as a model without housing.

Code reading in tube sorters

Requirement:

Prior to further processing, 1D-/2D-codes must be read for sorting.

Solution:

The DCR 55 1D-/2D-code readers can read codes in a large reading field. For very restricted installation situations, the DCR 50 is available without housing.

LSIS 220

The LSIS 220, with its optimized optics and resolution, offers large function reserves for reliable code reading, even while in motion. It quickly and reliably detects bar codes, stacked codes and 2D-codes.

Advantages for you

- Improved optics for larger read field and in-focus detection all the way to the edge areas, optimized resolution of 844x640 pixels for fast code reading

- Detection of 2D-codes, stacked codes and bar codes

- RS 232 or USB interface

- Switching input (trigger)

- Trigger button for manual activation and parameterization

- Construction without mechanically moved parts, robust metal housing with glass window and degree of protection IP 65 make the devices very well suited for industrial use

- Extremely small construction size, also for installation under difficult conditions

Applications

Manual code reading and reading in presentation mode

Requirement:

In assembly processes in which large, various components are moved by hand, both automatic as well as manual code reading must be possible.

Solution:

The LSIS 220 1D-/2D-code readers are equipped with various trigger options for automatic and manual operation.

Overview of technical data

| DCR 50/55 miniature scanner | Simple Vision Sensor DCR 1048i | DCR 200i compact scanner | LSIS 220 compact scanner | |

| Description | Compact 1D- and 2D-code readers | 1D-/2D-code reading with one image processing sensor Enhanced reading algorithm specially for DPM codes | Fast 1D- and 2D-code reading with modular design | Compact 1D- and 2D-code reading |

| Areas of application | Code reading on objects at a standstill or with slow movement speed in constrained spaces | Code reading on packaging for quality assurance or for detection of alignment on conveyor lines, multicode decoding, DPM code reading | Code reading on objects with high movement speed | Manual code reading and reading in presentation mode |

| Integrated interfaces | RS232; USB | I/O, TCP/IP, PROFINET, FTP or SFTP | RS232/422; TCP/IP; PROFINET; EtherNet/IP | RS232; USB |

| Reading range | 30 – 425 mm | 50 - 2,000 mm, depending on optics | 40 – 800 mm | 50 – 330 mm |

| Image resolution | 1,280 x 960 pixels | 1,440 x 1,080 pixels; 736 x 480 pixels | 1,280 x 960 pixels | 844 x 640 pixels |

| Modulus size | 0.127 – 0.528 mm | 0.1 – 1 mm | 0.1 – 1 mm | 0.127 – 1 mm |

| Ambient temperature (operation) | 0 – 50 °C | 0 ... 50 °C | 0 – 50 °C (without heating), –30 – 50 °C (with heating) | 0 – 40 °C |

| Dimension (W x H x L) | DCR 50: 31.6 × 12.7 × 27.5 mm DCR 55: 31.5 × 20 × 40.3 mm | 45 x 85 x 35 mm | 43×61×44 mm | 40×32×47 mm |

Article list

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: UPC, 2/5 Interleaved, Aztec, Codabar, Code 128, Co...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: EAN 8/13, 2/5 Interleaved, Aztec, Codabar, Code 12...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: GS1 Databar, 2/5 Interleaved, Aztec, Codabar, Code...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Code 32, 2/5 Interleaved, Aztec, Codabar, Code 128...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Codabar, 2/5 Interleaved, Aztec, Code 128, Code 32...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Code 39, 2/5 Interleaved, Aztec, Codabar, Code 128...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: GS1 Databar Stacked, 2/5 Interleaved, Aztec, Codab...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: GS1 Databar Stacked, 2/5 Interleaved, Aztec, Codab...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Pharma Code, 2/5 Interleaved, Aztec, Codabar, Code...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: Code 128, 2/5 Interleaved, Aztec, Codabar, Code 32...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: EAN 8/13, 2/5 Interleaved, Aztec, Codabar, Code 12...

- Series: DCR 200i, DCR 200i

- Switching principle: MOSFET semiconductor, MOSFET semiconductor

- Code types, readable: GS1 Databar Stacked, 2/5 Interleaved, Aztec, Codab...