Color sensors

Your benefit

- Versatile use thanks to operating ranges of up to 150 mm and up to seven color settings

- Simple operation and parameterization via integrated display or IO-Link

- New application-optimized variants

- Detection of glossy surfaces through luster suppression

- New brightness evaluation with autocorrect enables a large tolerance in object guidance or distance-independent color recognition up to 65 mm

- Up to 7 colors can be evaluated with three binary coded outputs

- Optimized for use in demanding environments thanks to robust die-cast zinc housing with IP67 and IP69 protection classes, as well as ECOLAB certification

Highlights

Simple operation: Quick teach-in process and seven color settings

The new CRT 648 color sensors are easy and intuitive to operate with a large, integrated LC display with keypad. The status of the switching outputs, a current color value output or the signal quality can be displayed as selected. If different product variants are tested in one system, up to seven color settings can be saved on the sensor and tested simultaneously. The large operating range opens up further possibilities: This means that one sensor can easily be used for different tasks – ensuring flexibility with increasing variation and reducing the outlay for additional sensors and set-up times.

Detects even subtle color differences, including in challenging conditions

Glossy objects are always a challenge for optical sensors. The new CRT 648-32.G color sensors are equipped with a polarization filter for reliable gloss detection. The evaluation of an object’s brightness, depending on its distance from the sensor, pose a further color recognition challenge. The CRT 648 color sensors’ brightness evaluation with autocorrect enables reliable and distance-independent color detection up to 65 mm.

Transparency and remote access via IO-Link

The new CRT 648 series color sensors can be set either remotely by teaching in via cable or via IO-Link, which is much more convenient. The format change can be simplified considerably via IO-Link and additional data can be recorded from the sensors.

The process at a glance:

- Extensive timer functions for switch-on/-off delay and pulse suppression

- Exact production figures known at all times thanks to the internal object counter

- Real-time signal information as RGB color value output via IO-Link

- Further diagnostic data such as temperature, signal quality, switching operations

Applications

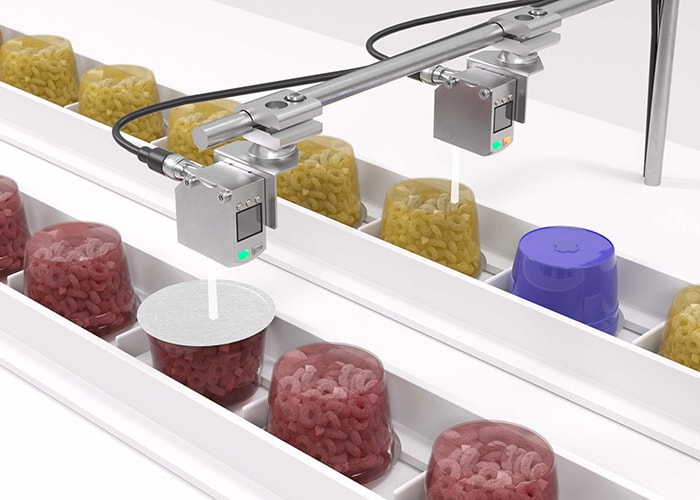

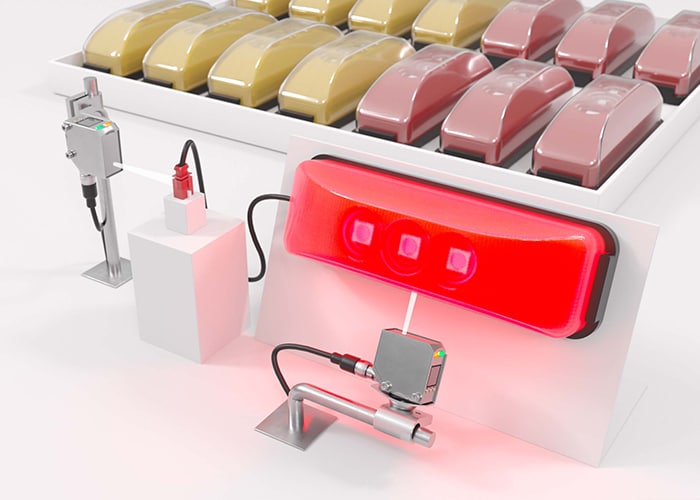

Final inspection in food packaging

Requirement:

In a packaging system, the color of cereal bowls must be checked before they are placed in the container packaging. As the bowls are to be packaged according to type, it must be ensured that the same color comes off the conveyor belt every time.

Solution:

The new CRT 648 color sensors can be taught up to seven colors. They are equipped with a large light spot and reliably detect the colors of both the packaging and the cover. This way, incorrect or defective objects can be reliably distinguished. The large operating range of up to 150 millimeters ensures reliable detection, even when switching to other formats.

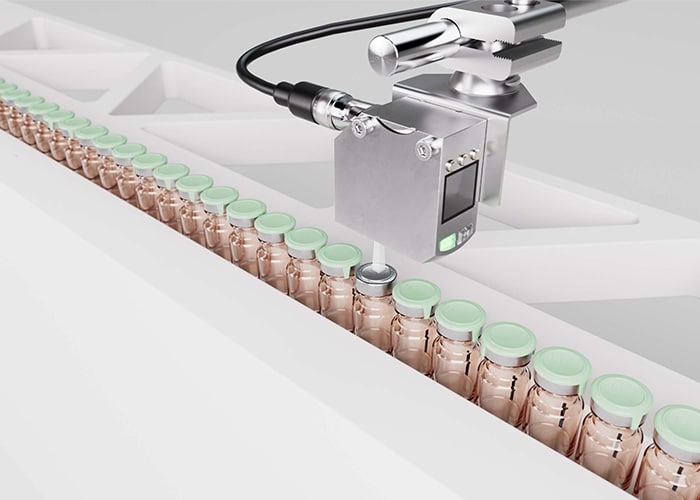

Monitoring of vials in pharmaceutical packaging

Requirement:

The quality requirements for pharmaceutical packaging are high. Defective vials, for example without caps, must be detected on the conveyor belt and ejected. The high-gloss vial caps pose a challenge for sensors.

Solution:

The CRT 648 color sensors with luster suppression detect the high-gloss vial caps while ensuring process stability. Operating and adjusting the sensors is quick and easy thanks to the large LC display.

Automated checks in car manufacturing

Requirement:

In the automotive industry, the color of rear lights is to be checked automatically at an assembly station. Two process steps must be covered: In the first process step, the connector color must be tested, and different test programs are then run depending on this. The second step in this application is to evaluate the light color and intensity of the rear light. Neither the ambient light nor the employee at the workstation may impair detection.

Solution:

In the first process step, a CRT 648 color sensor checks the color of the connector. Another CRT 648 checks whether the rear light has the correct light color and intensity.

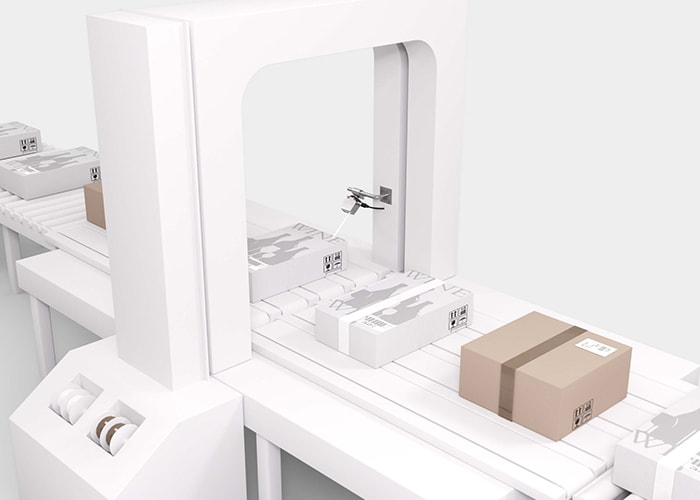

Strapping machine for carton packaging / sealing

Requirement:

Different carton packaging items run on a conveyor belt. The appropriate strapping should be automatically selected to match the carton color.

Solution:

The CRT 648 series color sensors detect the carton color and transmit the information to the strapping machine. This allows the system to select the appropriate strap color.

Technical features

| Feature | CRT648-32.G/L44-M12 | CRT648-60/LT-M12 | CRT648-60/L44-M12 | CRT648-150/LT-M12 | CRT648-150/L44-M12 |

| Housing material | Metal, die-cast zinc | Metal, die-cast zinc | Metal, die-cast zinc | Metal, die-cast zinc | Metal, die-cast zinc |

| Operating range | 18 … 32 mm | 18 … 60 mm | 18 … 60 mm | 20 … 150 mm | 20 … 150 mm |

| Light spot size | 6x6 mm @ 25 mm | 4x4 mm @ 40 mm | 4x4 mm @ 40 mm | 8x8 mm @ 60 mm | 8x8 mm @ 60 mm |

| Number of colors | 7 | 1 | 7 | 1 | 7 |

| Number of switching outputs | 3 | 1 | 3 | 1 | 3 |

| Switching output | Push-pull (PNP/NPN configurable) | Push-pull | Push-pull (PNP/NPN configurable) | Push-pull | Push-pull (PNP/NPN configurable) |

| Switching input | Configurable (Teach, Trigger, Key Lock) | Teach | Configurable (Teach, Trigger, Key Lock) | Teach | Configurable (Teach, Trigger, Key Lock) |

| Switching frequency configurable | 3 … 500 Hz | 3 … 3000 Hz | 3 … 3000 Hz | 3 … 3000 Hz | 3 … 3000 Hz |

| Ambient temperature (operation) | -20 … +55 °C | -20 … +55 °C | -20 … +55 °C | -20 … +55 °C | -20 … +55 °C |

| IO-Link data output | Switching outputs or color value output | Switching output | Switching outputs or color value output | Switching output | Switching outputs or color value output |

| Protection class | IP 67, IP 69 | IP 67, IP 69 | IP 67, IP 69 | IP 67, IP 69 | IP 67, IP 69 |

| Certification | CE, UL, China RoHS ECOLAB, UKCA | CE, UL, China RoHS ECOLAB, UKCA | CE, UL, China RoHS ECOLAB, UKCA | CE, UL, China RoHS ECOLAB, UKCA | CE, UL, China RoHS ECOLAB, UKCA |

| Connection | M12 (5Pin) | M12 (4Pin) | M12 (5Pin) | M12 (4Pin) | M12 (5Pin) |