Absolute hygiene

Technology report

Hygiene sensors series 53C and 55C

Hygiene-sensitive production and packaging processes require sensors that meet the most stringent requirements. Leuze makes this possible with sensor series intended for the food industry and with its many years of application know-how.

There are few industries where the demands placed on the sensor systems are as great as they are in the food industry. Whether sausage or cheese, confectionery or pastries, dairy or beverages: Hygiene is always a key factor when processing and packaging the products. Sensors in these areas must be resistant to intensive cleaning and disinfection cycles. The technology must also be able to withstand considerable fluctuations in temperature. With its new miniature sensors in stainless steel housings, Leuze fulfills all the important requirements of the food industry: chemical and thermal resistance, leak tightness and a hygienic product design. Protection classes such as IP67, IP68 and IP69K as well as ECOLAB, CleanProof+ and JohnsonDiversey certifications confirm that the devices operate properly at all times even in extremely harsh environments.

In the food industry, hygiene requirements are most strict wherever the food product or beverage is not yet protected by primary packaging. "This places high demands on sensors that are used for automation in these areas," says Heidi Wacker, Product Manager at Leuze. "Sensor systems must be high performance and hygienic, but also robust so that they can operate reliably in harsh environmental conditions." With its new solutions, Leuze ensures the following four key requirements for sensor systems used in the food industry:

|

1 Chemical requirements: high resistance Cleaning plays a major role in the packaging area of the food industry. Intensive cleaning processes, particularly after production runs, are necessary in order to remove food residue and to prevent bacterial carry-over. There are many cleaning cycles, long exposure times as well as preliminary and main cleaning. Furthermore, the sensor systems must be able to deal with a broad range of different cleaning agents – from ECOLAB cleaners to various foam and disinfectant cleaners that may be acidic or alkaline. To make sure that the sensors optimally withstand the cleaning agents, Leuze checks the devices using the ECOLAB test and also CleanProof+ and JohnsonDiversey procedures. This ensures the long-term resistance of the sensor housing. |

3 Leak tightness: reliably waterproof As the sensors are exposed to continuous wet conditions and humidity during cleaning and because high-pressure water jets are additionally used, absolute leak tightness is essential. Leuze always tests all sensors using leak testing equipment. The sensors intended for the food industry meet the demands required for IP69K approval: They are tested using a steam jet with an extremely high water pressure of up to 10,000 kPa and a temperature of up to 80 °C. The distance to the sensor during testing is very close at just ten centimeters. Furthermore, the sensor is exposed to the steam jet from different angles in order to simulate cleaning as realistically as possible. |

|

2 Thermal requirements: major differences in temperature Major differences in temperature exist particularly when food is placed in its primary packaging. For example: Owing to the sensitive foodstuffs handled in meat processing, the temperatures often range from 5 to 10°C. In contrast, however, cleaning is performed at extremely high temperatures. "Here, we again play it safe with our sensors and always test the products in several ways: in the climate chamber, by thermal shock testing and also by means of a steam jet test," explains Heidi Wacker. |

4 Materials/product design: hygienic and food-safe Sensors installed in packaging machines should be made of material that is approved for contact with food. Furthermore, the devices must be designed in such a way that they can be cleaned easily. In addition, no bacteria and no food residue are allowed to accumulate. For this reason, smooth surfaces without gaps and cavities are required. Leuze meets these requirements by implementing a hygienic product design and using selected FDA-compliant materials. This means that Leuze sensors for the food industry have a stainless steel housing as well as glass-free and scratch-resistant optics covers. |

|

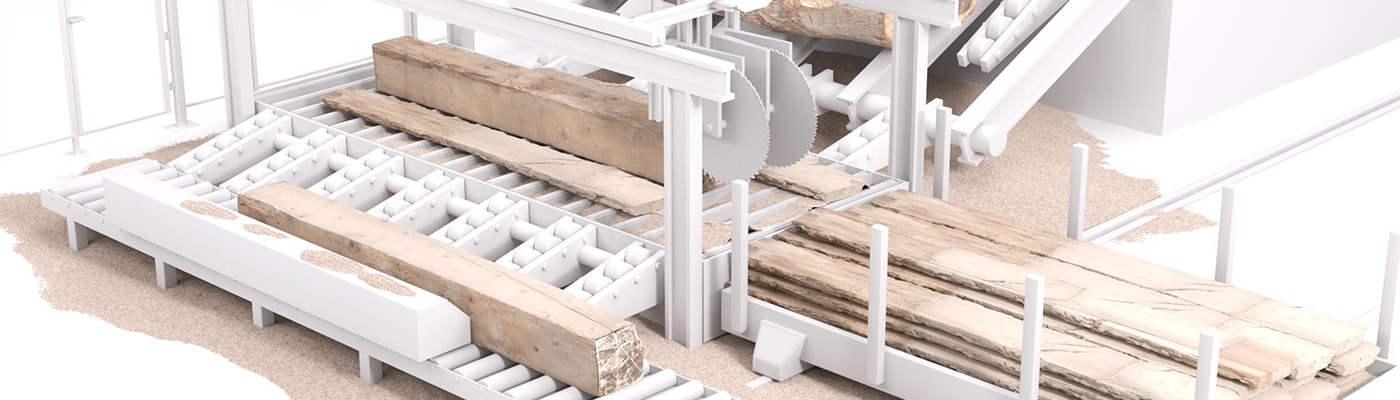

Leuze 53C series diffuse sensors have a hygienic design without drilled holes and are suitable for areas of application with direct contact with food. They also reliably detect the leading edges of cut-good products. |

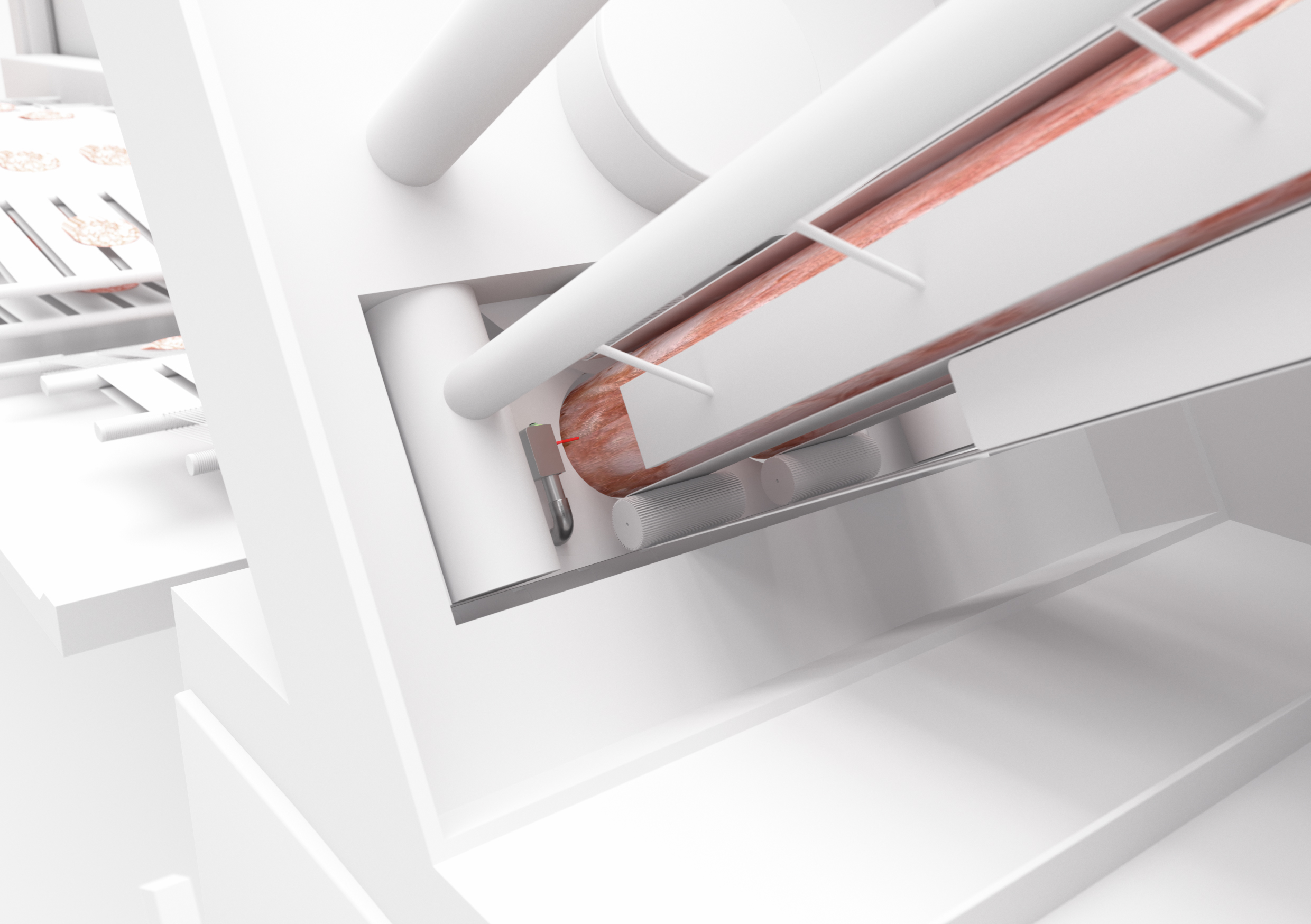

Reliably detecting the fill level of aqueous liquids in containers is one of the most demanding detection tasks. This requires particularly powerful sensor solutions such as the throughbeam photoelectric sensors of the 55C series from Leuze, which have been specially optimized for this application. |

|

In a filling system for milk bottles, the position of the bottles must be reliably and precisely detected on the conveyor belt for the subsequent packaging steps in the system. The PRK55C.TT3 retro-reflective photoelectric sensor also reliably detects transparent containers. |

In the food industry, sausage is delivered in large bars and cut into thin slices in a cutting machine. The HT53C.S diffuse sensor in Hygienic Design reliably monitors the product infeed at the sausage cutting machine. |

Precise and robust at the same time

The requirements make it clear that suitable sensor systems are needed for hygiene-sensitive production and packaging processes. To this end, Leuze has specially developed the 53C and 55C sensor series. They are characterized by the housing made of high-quality, particularly smooth V4A stainless steel and the glass-free, scratch-resistant optics cover. The sensors can thus withstand demanding cleaning and disinfection cycles as well as large temperature fluctuations.

Anyone wanting to be on the safe side when it comes to sensor systems used in the food industry should opt for a sensor manufacturer with extensive expertise in this area. Heidi Wacker explains: "Leuze not only understands the challenges in hygiene-sensitive environments, but has for decades worked closely with its customers from the food industry. We implement the Sensor People's comprehensive application knowledge in optimum sensor solutions for every requirement." The high-tech product range includes a number of different sensors for the field of automation technology. For example, switching and measuring sensors, identification systems, data transmission and image processing solutions as well as safety components, services and holistic solutions. Another advantage: Leuze covers not only a sub-process, but provides its customers from the food industry with assistance from the first to the last step in the packaging process completely and at all times.

Food-safe in stainless steel

Leuze has developed the sensors of the 53C and 55C series especially for hygiene-sensitive production and packaging processes. They can be used very flexibly as throughbeam photoelectric sensors, retro-reflective photoelectric sensors or diffuse sensors. Depending on the model, Leuze solutions reliably detect glass, PET, film or small parts. The fill level of aqueous liquids can also be easily detected. The 53C and 55C sensor series are dustproof and waterproof and meet the requirements of protection classes IP67, IP68 and IP69K. The housing is consistently designed to prevent bacterial carry-overs and contamination. Smooth contours without fastening holes prevent deposits. A special fastening concept of the 53C series in hygienic design also contributes to this: The sensor and the machine have a gastight connection via the mounting trunnion. Useful: The sensors can be configured, operated and maintained via IO-Link.

|

Heidi Wacker Product Manager at Leuze |

Leuze electronic GmbH + Co. KG In der Braike 1, 73277 Owen T +49 7021 573-5514 info@leuze.com www.leuze.de |