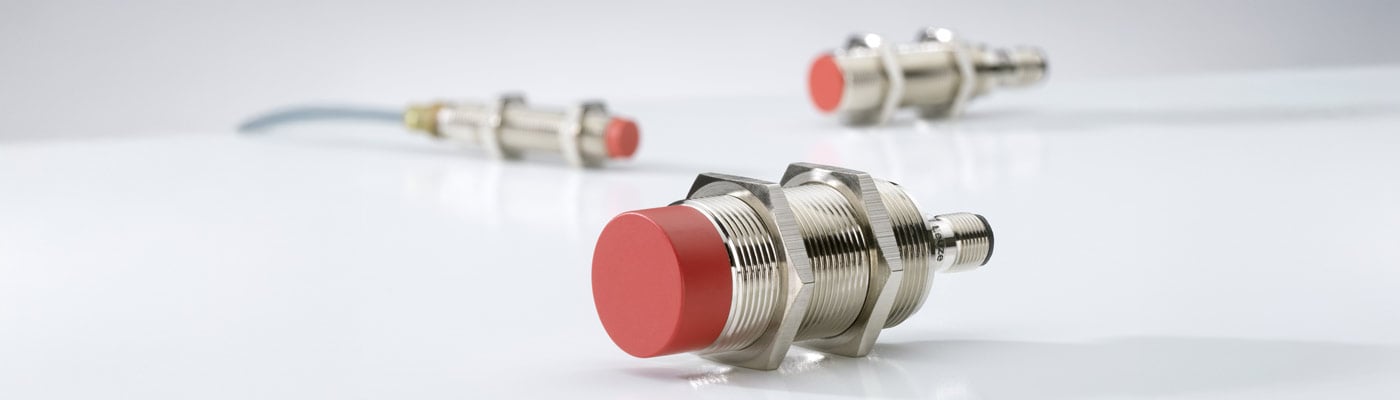

Inductive switches

The Leuze product range includes a wide variety of standard and special sensors that are available in many different designs and have already been tried and tested millions of times by our customers.

In particular our extremely robust all stainless steel sensors, sensors with extended switching distance or miniature sensors for extremely constrained spaces have again and again proven to be ideal for challenging applications.

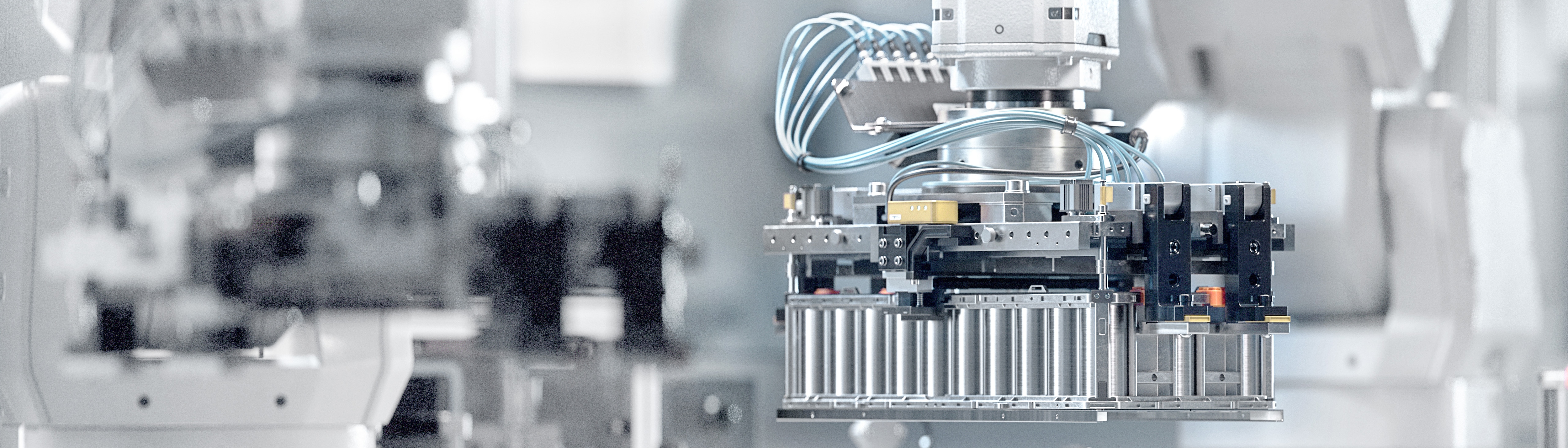

Inductive sensors with impressive cost effectiveness: The new IS D series for industrial automation

The new IS D series’ inductive sensors offer a universal and reliable solution for the contactless detection of metallic objects in various industries. The portfolio includes the cylindrical designs M8, M12, M18 and M30 in the embedded and non-embedded installation variants. The sensors are easy to install thanks to their external thread and are UL-certified to meet the requirements of international standards. The excellent price-performance ratio makes the IS D series a cost-effective solution for projects with a large number of sensors.

Your benefit

- For a wide range of applications in various industries

- Excellent price-performance ratio

- Up to 2x switching distance

- Common cylindrical designs with external thread

- Robust bending protection (for cable variants) for variable applications

- UL-certified

Applications

Load receptacle end position detection

Requirement:

Solution:

Dancer roll position detection

Requirement:

Solution:

Inductive sensors with long operating range

New inductive sensors for switching distances up to 40 millimeters

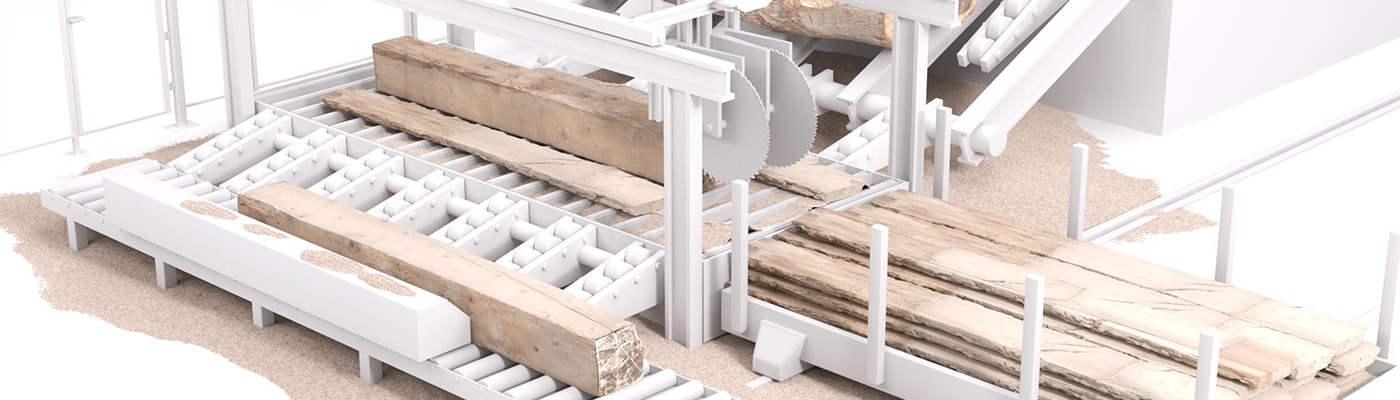

Inductive sensors are used in all industries for the contactless detection of metals. The position detection of moving machine components is important for controlling the mechanics. Inductive sensors are the first choice, even if tools, input materials or end products made of steel, aluminum, copper alloys or stainless steel need to be detected.

Inductive sensors, also called proximity sensors, are known for reliably detecting metallic objects over short distances. Models with increased switching distances enable operating ranges up to three times longer than standard inductive sensors. The new sensors are therefore also suitable for applications with small installation spaces and/or large distances or tolerances – for example with inaccurate alignment, mechanical play or vibrations.

The new robust sensors with the designation IS 200MM.2 are made of nickel-plated brass and are available in cylindrical M12, M18 and M30 housings. They can even be used under high mechanical stress and provide highly accurate measurements and repeatability at a good price-performance ratio. The new sensors with switching distances of up to 40 millimeters can be installed quasi-flush or non-flush, depending on the respective application. The new sensors expand the existing inductive product portfolio.

Your benefit

- Cost-effective detection of metallic objects

- High switching distance enables machine concepts with larger tolerances

- Sensor installation at greater distances from the object reduces collisions

- Lower storage costs: Sensor models can be used for different ranges

- Robust design: Use in harsh environments with dirt or vibrations

- Mounting options for different applications: quasi-embedded and non-embedded

- Temperature range

Highlights

Long switching distance for reliable processes

Lower storage costs through standardization

The long switching distance of the new IS 200 series’ sensors means one sensor model can be used for several operating ranges. Standardizing designs can reduce stocking costs.

Applications

Frontal detection in the gantry crane

Requirement:

Solution:

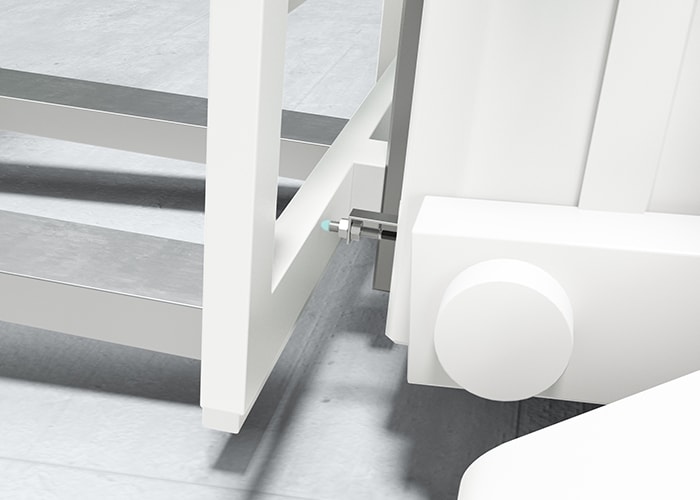

Skid conveyor system position control

Requirement:

Solution:

Object detection of product carriers

Requirement:

Solution:

Technical features

| Parameter | ISS 212MM.2 | ISS 218MM.2 | IS 230MM.2 |

| Operating range | 0-6 mm (quasi-embedded) 0-10 mm (non-embedded) | 0-12 mm (quasi-embedded) 0-20 mm (non-embedded) | 22 mm (quasi-embedded) 40 mm (non-embedded) |

| Response time | ≤ 20 ms | ≤ 20 ms | ≤ 20 ms |

| Repeatability | ≤ 10% | ≤ 10% | ≤ 10% |

| Hysteresis | 1 – 20% | 1 – 20% | 1 – 20% |

| Switching frequency | ≤1300 Hz (quasi-embedded) ≤2000 Hz (embedded) | ≤600 Hz (quasi-embedded) ≤700 Hz (non-embedded) | ≤100 Hz (quasi-embedded) ≤100 Hz (non-embedded) |

| Connection type | M12 4-pin | M12 4-pin | M12 4-pin |

| Housing dimensions | M12 x 51 mm (quasi-embedded) M12 x 54 mm (non-embedded) | M18 x 55 mm (quasi-embedded) M18 x 64 mm (non-embedded) | M30 x 75 mm (quasi-embedded) M30 x 87 mm (non-embedded) |

| Temperature range | -25°C … +70°C | -25°C … +70°C | -25°C … +70°C |

| Protection class | IP 67 | IP 67 | IP 67 |

Article list

Product selector

- Series: D30

- Design: Cylindrical, 30 mm

- Typ. operating range limit Sn: 15 mm

- Series: D30

- Design: Cylindrical, 30 mm

- Typ. operating range limit Sn: 15 mm

- Series: D30

- Design: Cylindrical, 30 mm

- Typ. operating range limit Sn: 10 mm

- Series: D30

- Design: Cylindrical, 30 mm

- Typ. operating range limit Sn: 10 mm

- Series: D18

- Design: Cylindrical, 18 mm

- Typ. operating range limit Sn: 16 mm

- Series: D18

- Design: Cylindrical, 18 mm

- Typ. operating range limit Sn: 16 mm

- Series: D18

- Design: Cylindrical, 18 mm

- Typ. operating range limit Sn: 16 mm

- Series: D18

- Design: Cylindrical, 18 mm

- Typ. operating range limit Sn: 16 mm

- Series: D18

- Design: Cylindrical, 18 mm

- Typ. operating range limit Sn: 8 mm

- Series: D18

- Design: Cylindrical, 18 mm

- Typ. operating range limit Sn: 8 mm

- Series: D18

- Design: Cylindrical, 18 mm

- Typ. operating range limit Sn: 8 mm

- Series: D18

- Design: Cylindrical, 18 mm

- Typ. operating range limit Sn: 8 mm