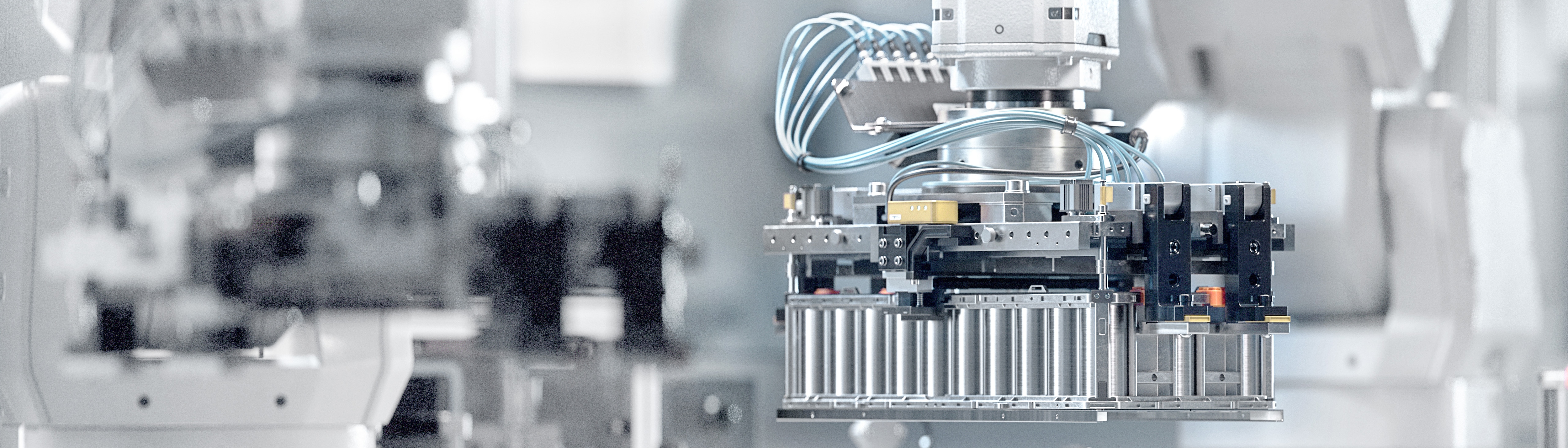

Future-oriented solutions for the wood processing industry

As an experienced manufacturer of industrial sensors, we have extensive expertise in sensor applications for the wood-processing industry. Our innovative products offer efficient and future-proof solutions for the wood-processing industry’s specific challenges.

Renowned machine manufacturers are setting new standards and benchmarks in automated systems. Intelligent sensor technology provides the basis for this by offering maximum reliability and maximizing system availability.

Our sensors, which are Industry 4.0-capable, enable transparent and optimized processes. Modern cloud solutions ensure process data is available worldwide for system maintenance and monitoring at any time.

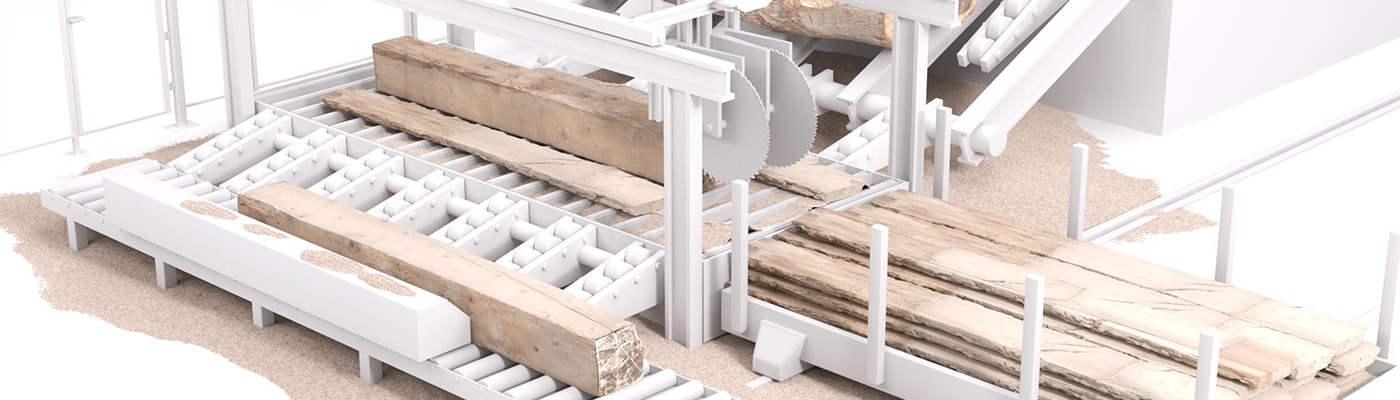

Object detection in the feed section / Presence inspection

Requirement:

The wooden parts are transported between the processing stations via conveyors. To control the transport as well as each individual process, each plank must be detected in its exact position.

Solution:

The HT 46C or HRT 8 series’ optical sensors include a diffuse sensor model with a large detection range that reliably detects planks and boards even if they have structural or color differences.

Object detection in dirty environments / Presence inspection

Requirement:

In wood processing, the wood objects must be detected for process control in a way that is insensitive to dust and dirt.

Solution:

Series 46 and Series 49 diffuse sensors with high function reserve and energy-intensive light spot are suitable for object detection in dirty environments. The adapted models with enhanced dust resistance, such as the HT46C.E-type sensor, are even more robust.

Object detection in dirty environments

Requirement:

To start an automated saw or processing station, the wood plates must be detected regardless of their surface, even in particularly dusty or dirty environments.

Solution:

The capacitive sensors in the M18 or M30 models for ranges of up to 60 mm can be easily integrated into the conveyor system. They detect wood plates regardless of color or any falling chips. The LCS1 series with metal sleeve is a very robust version. The standard LCS2 design with plastic housing can also be used as an option.

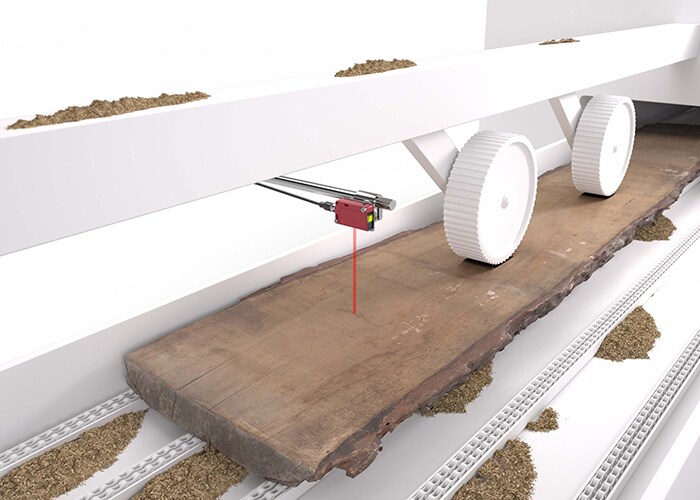

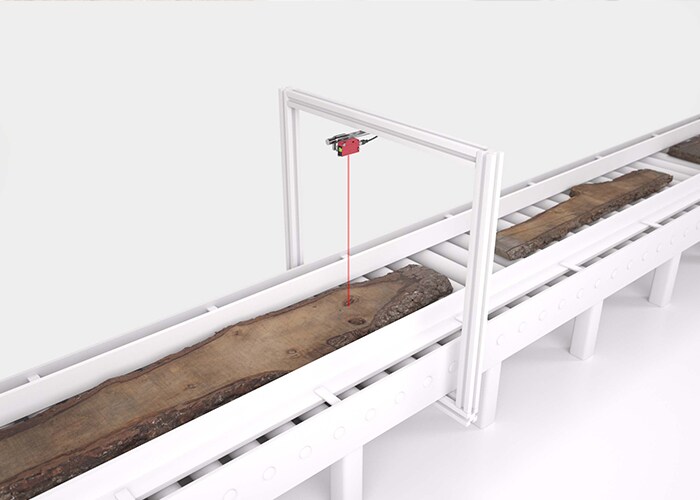

Length calculation

Requirement:

The length of wooden parts must be determined flexibly from the raw wood to the wooden slats at a constant conveyor speed with the aid of sensors in the control system.

Solution:

The length of the wooden parts can be reliably determined using optical sensors with a short response time. The (particularly precise) laser diffuse sensors of the HT46CL series are suitable for this purpose, or the HT49 or HT25 series with LED light spot, depending on the required range.

Access guarding in the gantry crane area

Requirement:

The crane’s automated area must be safeguarded to ensure smooth operation. To this end, optoelectronic safety sensors are to be used to minimize the impact on access points.

Solution:

Mounted in a protected position in the UDC device columns, even large areas can be protected with the MLD safety light barriers in 2, 3 or 4 beams up to 80 m. Mirror columns are available for beam deflection at the corners. If a more flexible fastening is required, the SLS46C light beam safety device is suitable as a throughbeam photoelectric sensor for the setup of a multi-beam system.

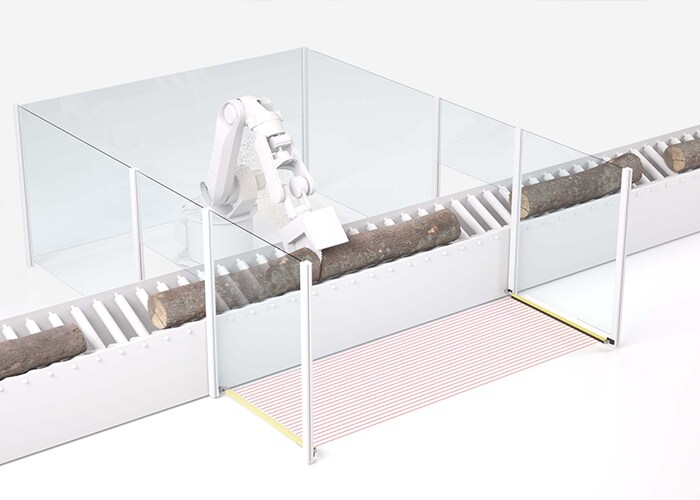

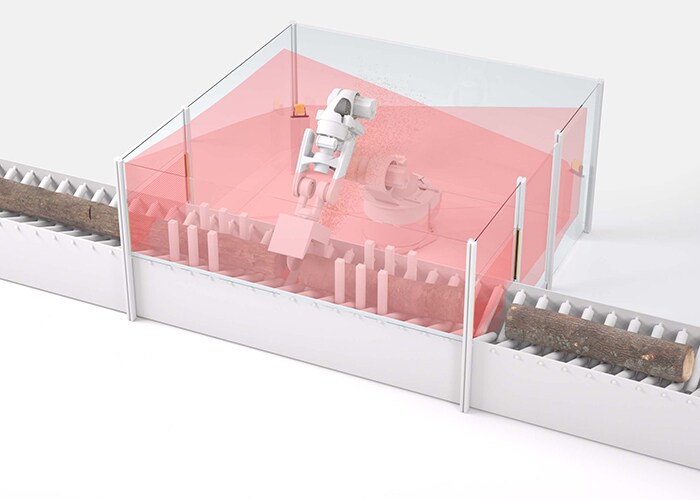

Personal protection in the robot area / Points of operation

Requirement:

All areas in front of machine openings and feeds close to the point of operation must be protected with high-resolution safety sensors to detect even small interruptions.

Solution:

With staggered resolutions from 14 mm and lengths of up to 3000 mm, the MLC safety light curtains with additional features offer a customized solution. For simple standard protection, the ELC can also be used for openings up to 1500 mm.

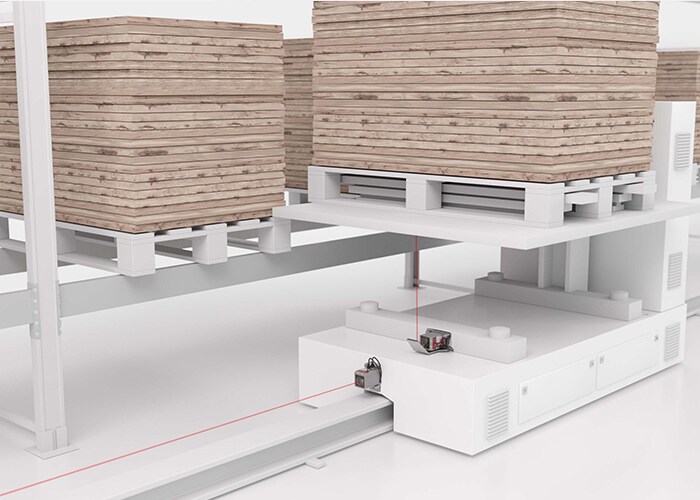

Positioning in the high-bay warehouse

Requirement:

The automatic transport of panels or timber stacks in the warehouse requires fast and precise positioning of the transfer car or stacker crane. This requires position sensors with suitable operating ranges and accuracy.

Solution:

The robust AMS 100 or AMS 300 laser positioning systems are available in staggered operating ranges of up to 300 m and with various interfaces for connection to the PLC.

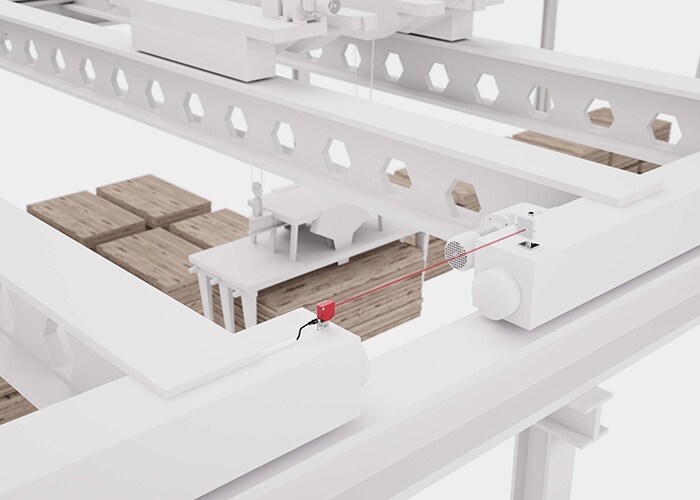

Collision detection / Positioning

Requirement:

In systems with several automatic cranes on one rail, collisions must be avoided. The sensors’ operating ranges must be selected according to the travel speeds.

Solution:

The ODS 96/10 or HT10/96 series’ optical sensors can be used for collision monitoring up to 25 m against a reflector, with analog or digital signal options. A sensor with a reinforced plastic housing (SR10) or metal housing (SR96) can be used depending on the requirements.

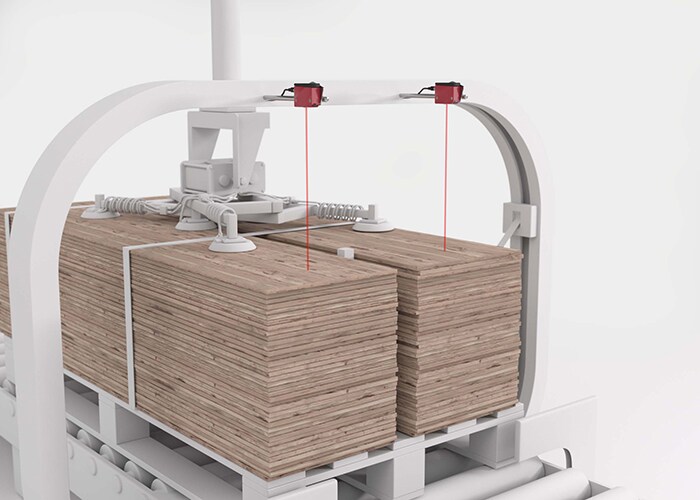

Stack height, dimension, contour or volume measurement

Requirement:

Automatic stacking of the sawn or processed objects requires height monitoring to ensure uniform stacks for control purposes. To allow for different widths, monitoring must be carried out from above.

Solution:

Depending on the stack height, a measuring sensor from the ODS 110 series or a diffuse sensor with several switching points (ToF) can be used for height measurement or height monitoring from above. Particularly robust variants in a metal housing are available as ODS 96.

Access guarding

Requirement:

An additional restart interlock is designed to prevent accidents in monitored areas, including when cutting to size. This sawing environment requires a high degree of dust resistance.

Solution:

The safe LBK radar system is robust against dirt. At least two devices are required for area monitoring in the sawing cell. Up to six sensors can be combined with one LBK controller depending on the cell size.

Wood conveyor system / Presence control

Requirement:

An easily integrated sensor, which can be installed in the sides of the conveyor, for example, must be used to detect the wooden parts. The function must also be reliable in dusty and possibly slightly vibrating environments.

Solution:

The PRK 328 series’ robust cylindrical sensor with angled optical outlet reduces the installation space required and increases availability even in dusty environments. The metal sleeve and nuts ensure vibration-proof installation.

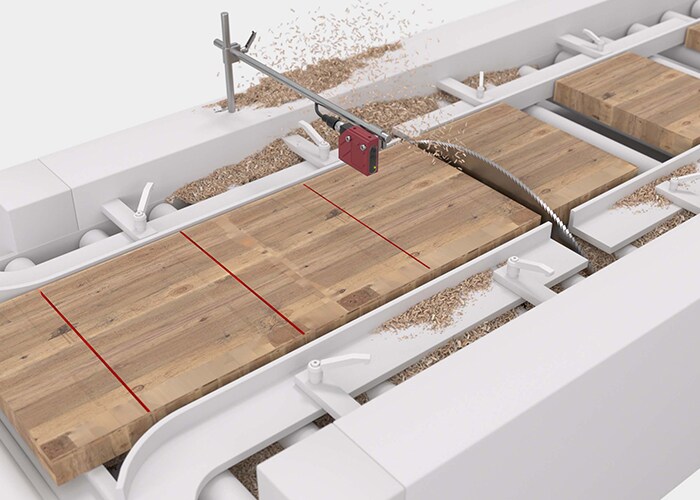

Marking detection and cutting control

Requirement:

For automated sawing with different types of wood, a mark applied in a defined color must be reliably detected. This allows individual lengths to be cut.

Solution:

The LRT8 luminescence sensor detects certain ‘pigments’ in the mark on any wood surface for sawing control and is very resistant to soiling thanks to the UV light.

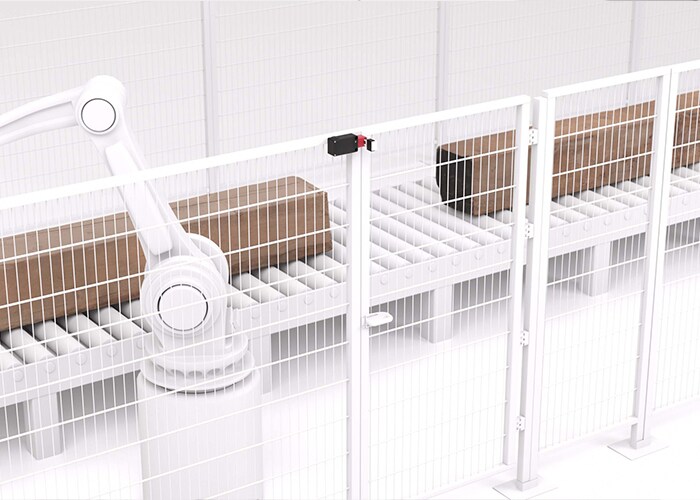

Protective door guard interlocking / Access guarding

Requirement:

The status of system access points, e.g. service doors, must be monitored during operation for occupational safety reasons.

Solution:

The compact switches and guard interlockings from the L100 series or the particularly robust version from the L 300 series are suitable for protective door access guarding. All guard locking devices have OSSD outputs.

Safety function

Requirement:

Safety sensors are combined for the safety function. Suitable switching devices / safety relays must be selectable for this purpose.

Solution:

With a fixed function as an MSI-SR safety relay or freely programmable as an MSI 400 safety control and intuitive programming software, these safety products provide customized safety solutions.