Leuze presents the smallest safety laser scanner on the market

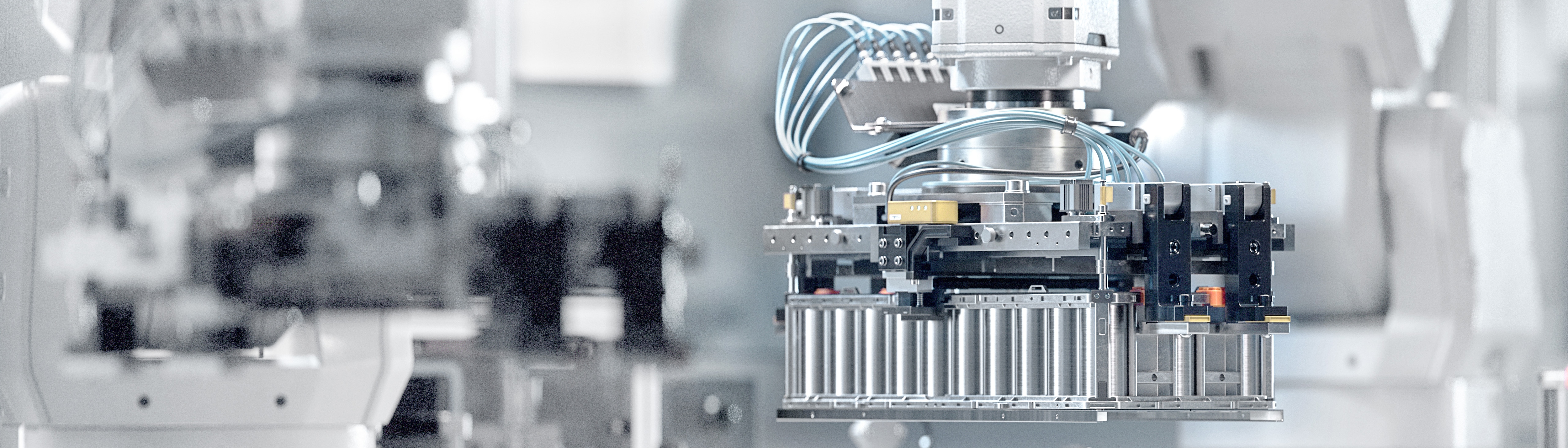

The new, ultra-compact RSL 200 safety laser scanner from Leuze safeguards machines, automated guided vehicles and robots. Thanks to its minimal dimensions, it is very easy to integrate even where space is limited.

Owen, Germany, 19 February 2025 – Small, smaller, RSL 200: With the RSL 200, Leuze is launching the smallest safety laser scanner on the market. The Sensor People are thus setting new standards in the miniaturization and integration of safety laser scanners. The exceptionally compact size and innovative connection technology allow unprecedented possibilities for sensor integration. The powerful device reliably safeguards machines, systems, automated guided vehicles and autonomous mobile robots. Thanks to its small dimensions the RSL 200 safety laser scanner is very easy to integrate, even where space is limited. The safety laser scanner adds an ultra-compact variant to the Leuze portfolio. The RSL 200 offers an operating range of three meters and a 275-degree scanning angle. For a greater operating range of up to 8.25 meters, system operators can rely on the RSL 400.

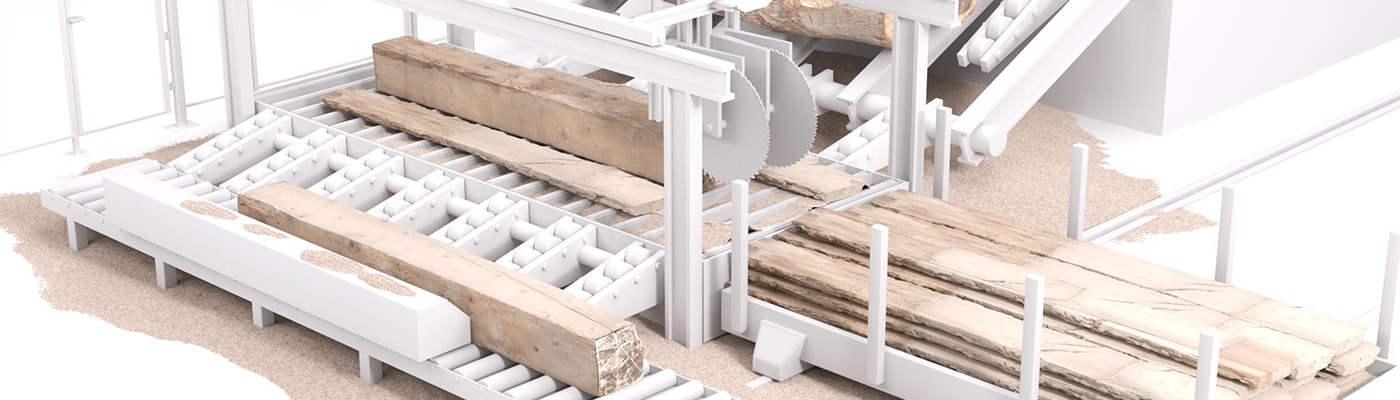

Flexible stationary use

With its configurable protective fields, the RSL 200 is ideal for area guarding and for applications with protective field switchover. In this way, the safety laser scanner detects anyone entering or staying in a machine or system’s monitored area. Thanks to its large scanning angle, it also safeguards two sides of a machine around a corner with just one device. The configurable protective fields allow the monitoring area to be conveniently adapted to the machine’s contours. In addition to the compact design, the laser scanner’s rotating M12 connection also helps make integration easier, as this standardized connection allows extremely flexible cable routing. This also reduces the space required and makes commissioning easier.

Space-saving solution for mobile use

The RSL 200’s minimal dimensions also make it the right choice for automated guided vehicles and autonomous mobile robots. The configurable and switchable protective and warning fields of the RSL 200 enable flexible protection. They allow the monitored areas to be optimally adapted to curved paths, different speeds and various load conditions. Omnidirectional vehicles can be safeguarded in all directions with the laser scanner: Only two diagonally mounted devices are required thanks to the 275-degree scanning angle. 32 switchable sets of protective and warning fields enable its speed and direction of travel to be continuously adjusted. Another advantage for mobile use: The RSL 200 is insensitive to shocks and vibrations.

Quick to commission and replace

The mounting bracket was specially developed for the RSL 200 to help speed up integration and commissioning. It allows the safety laser scanner to be easily aligned horizontally and vertically. This makes it particularly easy to set the scan level. The mounting bracket’s design is optimized for minimum space requirements.

If servicing is required, the laser scanner can be replaced quickly and easily with just four screws. No realignment is required thanks to the innovative mounting bracket. The RSL 200 also contains a removable configuration memory. This makes it easy to transfer the configuration to the new device.

App for convenient remote access

Practical: System operators can use the RSL 200 app to access status information and diagnostic data. All important information can be captured remotely via Bluetooth. This is particularly helpful if the RSL 200 is installed in system areas that are difficult to see or if access to the device is restricted. The machine can continue to work without disruption because you do not need to enter the protective field to read out the information. All messages are displayed in plain text in the app. Users can also send these directly to Leuze Service if required. Other interfaces such as USB and additionally Ethernet TCP / IP (for device variants RSL 230 and higher) offer additional configuration and diagnostics options.